REDUCE DOWNTIME AND BLOCKAGE COSTS WITH FLOVAC'S REAL-TIME MONITORING SYSTEM. HERE'S HOW.

Imagine this… you can know where and when stormwater enters your system plus know exactly where in a system you need to go at 2 in the morning when there’s a call out, or if you need to go out at all. What’s more, imagine that you understand exactly where to tune your sewerage system to get the lowest energy costs. Well Flovac’s remote monitoring of its vacuum sewerage system does it.

Flovac’s monitoring system highlights exactly why vacuum systems are starting to be the preferred sewer systems, even in areas where gravity-fed systems may be cheaper. Assets managers want control and they want to know what is happening in their system. And Flovac can deliver on this.

Imagine remotely changing the settings on your system to accommodate peak holiday events like the 4th of July or New Years Eve? Or to better handle severe storms and hurricanes from the safety of your home or desk? All of this is now possible.

Flovac’s innovative monitoring system user-focussed design and product improvements, have reduced many of the problems that plagued many vacuum systems sold in the seventies and eighties.

A key challenge for operators is keeping track of what’s going wrong when call-outs to a system are infrequent. Sewerage system operators want to rapidly know where a problem is, what the problem is and how to deal with it.

Asset Managers also need a clearer understanding of the performance of their sewerage system assets. They want the answers to questions like these. Do the operators need better training? Do assets need replacing or upgrading? What are the energy costs?

The installation of a Flovac’s Green Vacuum Sewerage monitoring system, either via cable or wireless, can reduce operational costs by 30-50% in certain systems, giving a payback period for the capital costs of less than 3 years.

Many utility companies and organisations with a reduction in staff numbers, need their sewer operators to perform many duties, many unrelated to the vacuum system which might only be a small component of their numerous assets.

Flovac’s Research and Development group have worked on a variety of monitoring systems for their vacuum system. The vacuum pump station has always had a form of monitoring, often interfacing with the clients SCADA system.

For the past ten years or more European standards have required that vacuum systems have a degree of monitoring for their vacuum valves and pits. Flovac’s R&D group has remained at the forefront of developing solutions for their clients throughout the world.

For a long time, many clients relied on the product improvements within the system, but Flovac’s monitoring systems have become so useful, easy to install and low cost that they have become a standard part of any system installation.

EASY TROUBLE SHOOTING AND RAPID SYSTEM ANALYSIS.

Sewer operators need and want to know;

- If a potential overflow was going to occur,

- Where in the system was a valve stuck open, and

- Where was infiltration occurring.

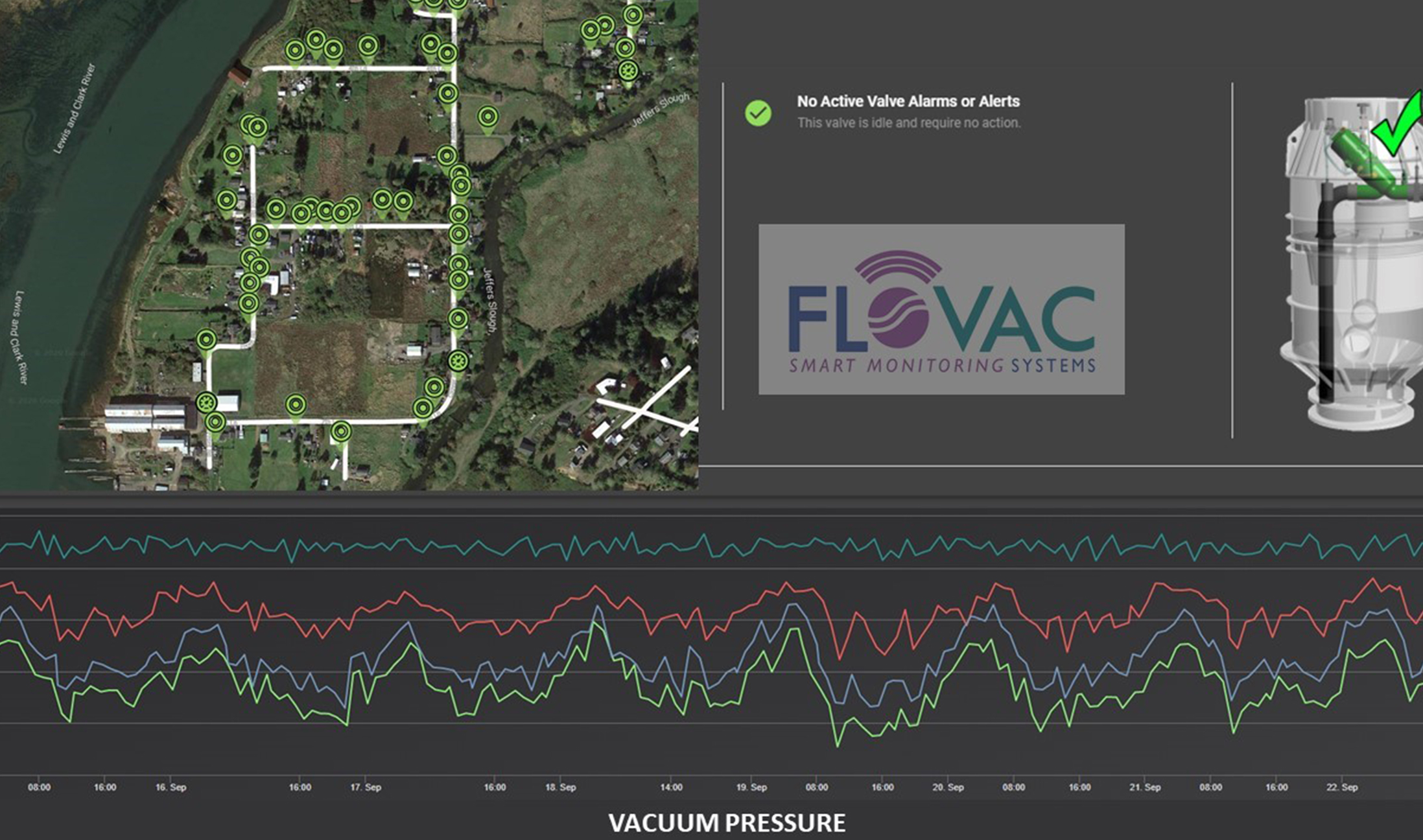

Flovac’s monitoring system answers all these questions. It gives the right insights at the right time, resulting in more efficient management and operational savings.

HERE'S WHAT OUR CLIENTS EXPERIENCE USING FLOVAC'S REAL-TIME MONITORING SYSTEM.

- They have reduced operator overtime costs as call-outs could be categorised between urgent (high level alarm) and non-urgent (valve open alarm). This reduced man-hours and also reduced the risks to operators of wandering around in the middle of the night, often during storms.

- The system’s high-level alarm in the pit of a potential overflow into someone’s yard or house, took away the single highest risk for many of the councils.

- Monitoring reduced operator man-hours as any faults could be located immediately without a long process of finding where a problem was.

- Our system’s monitoring dashboard gives visibility to see the vacuum pressure on each line highlighted area’s where line flooding might be occurring, reducing the risks of pit flooding.

- The automated air inlet system can be programmed to tune the system or change the air entering the system during seasonal population periods or extreme weather events such as storms, high tides etc. It also allows for easier staging of residential subdivisions when very few houses are connected to the system.

- There’s a reduction in man-hours spent tuning a system, as controller timing can be seen at the terminal which reduces energy costs within the systems.

- Flovac’s monitoring has fast and easy identification of any illegal storm water connections or other causes of infiltration.

All of Flovac’s operators love the convenience of getting all of the system’s operational information that they need directly to their smart phones.

This means that when they get an alarm, they know immediately what’s going on, how quickly they need to get there, and what they’re likely to find. They also find it extremely useful to be able to see what the vacuum pressure is at the VPS when they are out in the field.

The installation of a monitoring system, either via cable or wireless, can reduce operational costs by 30-50% in certain systems, giving a payback period for the capital costs of less than 3 years.

The Flovac monitoring system is able to be implemented onto other suppliers valves. If you’d like more information or a presentation about the monitoring system and its compatibility with your vacuum system please contact your closest Flovac office.